A selection of products and projects developed.

Projects

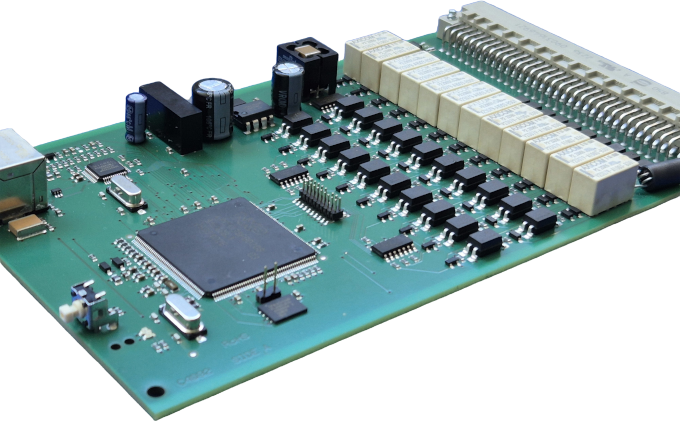

DP6000 Switching system

An existing product required a redesign to ensure long-term continuity for a system that had been in use for several years, which was no longer feasible with the current hardware. I contributed to the conceptual design, which led to the conversion of the existing I2C interface to Ethernet. The hardware was developed by Elexol BV, and I was responsible for writing the firmware.

An interactive web page was added to allow users to view the status and operate the interface without the need for additional software.

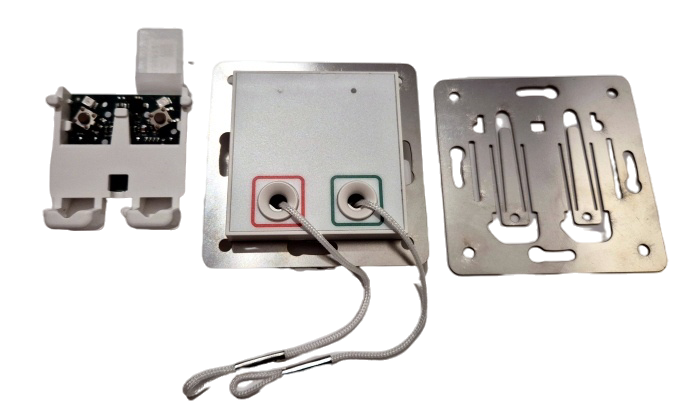

Pull Cord Unit

Development of a completely new concept for a pull cord unit, commonly used in healthcare settings. At my work with Schoonderbeek, I was asked to come up with a solution to simplify the pull cord unit. I developed an entirely new design that eliminates the need for screws, making the circuit boards smaller and easier to assemble.

I personally handled all aspects of the design, including creating the drawings for laser cutting the springs, injection molding the plastic components, and, of course, developing the embedded software for the unit.

Foil unit range

At my job at Schoonderbeek, we ran into the problem that there was a concept that needed to be renewed. Eventually, the question was asked to me, take another look at it. After some experimentation, I came up with the concept of these family foil units. The complete concept, including the magnetic plug, was developed by me. Colleagues have contributed with test fixtures and firmware.

Meanwhile, about 400,000 products have already been made in this family and the numbers are still steadily increasing.

Sed ut pers unde omnis iste natus error sit voluptatem accusantium dolor laudan rem aperiam, eaque ipsa quae ab illo inventore verit.